Ozone Water Treatment

Ozone has been in use for over a century to disinfect and treat water. North America is quickly becoming a major market for Ozone Generators and Ozonated products. Ozone has a number of advantages over “traditional” treatments such as Chlorine. Ozone is generated by Ozone Generators and is made from Oxygen in the air. This means that you never have to buy chemicals or other “consumables” to treat your water. Oxygen is abundant and free. There is never any need to haul chemicals, store chemicals on site, work with dangerous or toxic materials, determine proper mix ratios and other problems associated with chemical water treatment.

Ozone has been in use for over a century to disinfect and treat water. North America is quickly becoming a major market for Ozone Generators and Ozonated products. Ozone has a number of advantages over “traditional” treatments such as Chlorine. Ozone is generated by Ozone Generators and is made from Oxygen in the air. This means that you never have to buy chemicals or other “consumables” to treat your water. Oxygen is abundant and free. There is never any need to haul chemicals, store chemicals on site, work with dangerous or toxic materials, determine proper mix ratios and other problems associated with chemical water treatment.

Reliability, Modular Parts

As well, the systems are incredibly reliable. With advances in micro-electronics and modular design (snap-in boards and easily interchanged parts), Ozone Generators are reliable, self-metering and “smart” with features such as automatic flow control and metering. Generators do not require intensive maintenance or attention.

Once they are set up and running properly, there is not a lot of user intervention required. And they do an excellent job of sanitizing water. Ozone is the strongest commercially available oxidant in the marketplace. This means it can kill even chlorine-resistant bacteria. It also improves water taste and acceptability (a feature often not found in even the best chemical treatment systems). It precipitates iron and manganese, which means that these substances can be eliminated from the water. As well, it kills foul odors and tastes caused by Hydrogen Suflide, sulphur bacteria and other bacteria.

Operating Costs

Ozone operates for just pennies a day. A 4 gr/hr. Generator only uses 120 watts and only operates when water is flowing. With chemical systems, the costs to buy chemicals quickly add up to more than what an Ozone Generator would cost. Ozone (O3) is Produced from Oxygen (O2)

Ozone is produced from oxygen in the air. The Ozone Generators take Oxygen in the air and “manufacture” Ozone. Ozone generating systems are safe, reliable and the technology is well understood. Ozone has been extensively studied in clinical trials, universities, public water treatment facilities, wastewater systems and other systems worldwide for decades. They are safe, reliable and easily adapted to on-farm use. Once you have an Ozone Generator, there is never any need to buy chemicals or other on-going consumables, other than electricity.

Many cities and municipalities now rely on Ozone for primary oxidation and sanitation. Ozone is a superior sanitizer and can kill germs, viruses and bacteria thousands of times faster than chlorine. As well, unlike Chlorine, Ozone does not break down into carcinogenic substances.

Ozone System Objectives

Improvement in overall operation of the water treatment system by oxidizing iron, manganese, other minerals which are easily removed from the water system.

- Oxidation of organics, inorganics and killing of bacteria, germs and viruses.

- Significant improvement in water clarity and purity.

- No need to handle caustic chemicals such as Chlorine. (Ozone does not require chemicals for operation – Ozone is produced from Oxygen in the air.)

- Reduced liability in relation to water sanitation (destruction of chlorine-resistant bacteria) and employee liability (exposure to carcinogens in water caused by Chlorine byproducts).

- To produce crystal clear, healthy, good tasting water even under the most demanding circumstances.

Equipment, Maintenance

Ozone systems convert Oxygen (O2) in the air into Ozone (O3). Unless otherwise stated, Envron utilizes Corona Discharge Ozone Generators which incorporate air dryers for maximum Ozone production. These systems are robust, low-maintenance generators which incorporate micro-electronics and advanced safety features.

Ozone Generators

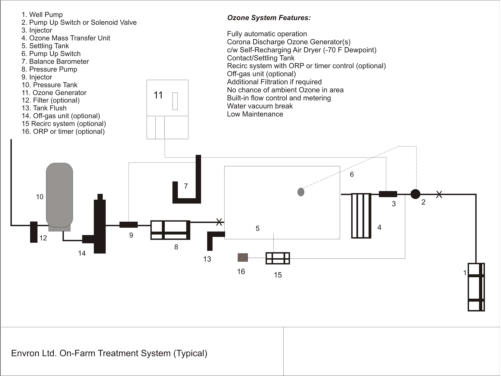

Ozone Generator operation is straightforward and is based on flow from the Mazzei Injectors. A flowmeter on the outside of the Ozone Generator shows airflow. A balance barometer is used to ensure no water enters the Ozone Generator and a valve controls how much airflow is allowed to flow through the Ozone Generator. If the Ozone Generator is to be installed in a warm environment (such as a mechanical room), a duct will be set up to draw air from a cooler part of the building

Safety, Ozone Contacting System

Ozone is metered into the water through the use of Mazzei Injectors. These injectors take water flow from your existing pump and create a suction or vacuum which pulls air through the Ozone Generators. This is a significant safety feature as Ozone cannot escape into the atmosphere in rooms where the Ozone Generators are housed. If the Ozone Generator leaks or a line breaks, air is simply pulled into the system, Ozone does not escape. (See schematic).

Contacting

The Ozone contacting system is one of the key components of the Ozone system. Ozone needs contact time and mixing in order to treat water. Envron systems use an initial Ozone manifold for contacting and a contact or settling tank to provide adequate time for the Ozone reactions to take place.

Water Treatment System Typical Flow Chart

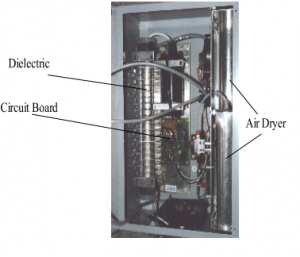

Ozone Generator Maintenance

If the Ozone Generator is set up with a clean airflow, routine maintenance will vary from six to eight months to one year or more. This maintenance would include cleaning the dielectrics in the generator, dusting the interior of the generator and reassembly. All electrical components in the generator are based on easily replaceable circuit boards or on an easily replaced dielectric. System failure is very rare. Air Dryer – Desiccant in the air dryer generally lasts from 2 – 3 years before needing replacement.